Fried Chicken Restaurant Equipment Setup : Complete Guide Leave a comment

Introduction: Why the Right Fried Chicken Restaurant Equipment Is Non-Negotiable

Fried chicken is one of the most profitable fast food categories—but it is also one of the most equipment-dependent. From managing hot oil safely to maintaining consistent crunch and flavor, success depends heavily on choosing the right fried chicken restaurant equipment from day one.

Many operators underestimate how specialized a fried chicken kitchen needs to be. Poor equipment choices lead to slow service, excessive oil costs, safety risks, and failed health inspections. This guide breaks down the complete fried chicken restaurant equipment setup, helping you meet operational demands, food safety standards, and long-term growth goals.

Understanding a Professional Fried Chicken Restaurant Equipment Setup

A fried chicken kitchen is built around speed, oil efficiency, and food safety. The fried chicken restaurant equipment you select must handle continuous frying, rapid turnover, and strict temperature control.

Core Operational Requirements

- High-capacity frying systems

- Efficient breading and prep stations

- Advanced oil management solutions

- Strong ventilation and fire protection

These elements form the foundation of a compliant and profitable fried chicken operation.

read more : Burger Restaurant Kitchen Equipment Requirements

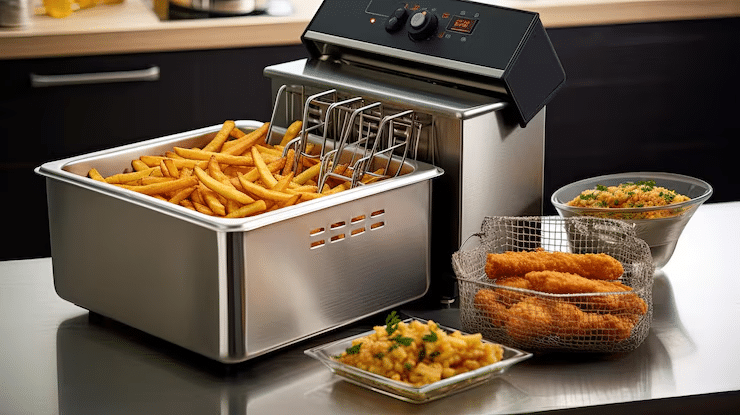

Fried Chicken Restaurant Equipment for Frying & Cooking

Frying equipment is the heart of your kitchen. Choosing the right fryers directly impacts food quality, safety, and output.

Essential Frying Equipment

- Pressure Fryers

Pressure fryers cook chicken faster while sealing in moisture, producing juicy meat and crispy skin. They are a cornerstone of professional fried chicken restaurant equipment for high-volume brands. - Open Deep Fryers

Open fryers are ideal for wings, tenders, fries, and side items. Many kitchens use a combination of pressure and open fryers to diversify menus. - Fryer Battery Systems

Multi-fryer configurations allow operators to cook different products simultaneously without flavor transfer—an important operational requirement. - Automatic Basket Lifts

These reduce labor strain, ensure consistent cook times, and improve safety around hot oil.

Fried Chicken Restaurant Equipment for Breading & Preparation

Consistency starts before the fryer. Proper prep equipment ensures uniform coating and reduces waste.

Prep Equipment Essentials

- Dedicated Breading Stations

Designed with flour wells, spice bins, and drip trays, breading stations are critical fried chicken restaurant equipment for maintaining workflow efficiency. - Refrigerated Prep Tables

Keep raw chicken at safe temperatures during marination and coating, supporting food safety compliance. - Marination Tubs & Holding Bins

Food-grade containers allow for consistent seasoning and batch preparation. - Stainless Steel Work Tables

Durable, easy-to-clean surfaces help maintain hygiene in high-volume kitchens.

Fried Chicken Restaurant Equipment for Oil Management

Oil quality directly affects taste, texture, and operating costs. Advanced oil systems are a smart investment.

Oil Management Equipment

- Built-In Oil Filtration Systems

These systems remove food particles and extend oil life, reducing waste and maintaining flavor consistency. - Oil Disposal & Transport Units

Safe oil handling is a key health and safety requirement in any fried chicken restaurant equipment setup. - Temperature Monitoring Controls

Prevent oil breakdown and fire hazards by maintaining optimal frying temperatures.

A well-planned layout reduces unnecessary movement, prevents cross-contamination, and optimizes staff productivity—making it a critical fast food kitchen cost factor.

Ready to upgrade your kitchen? Explore the best restaurant kitchen equipment in the UAE today and take your business to the next level. Click here to discover top-quality solutions that will streamline your operations and boost efficiency

Fried Chicken Restaurant Equipment for Refrigeration & Storage

Raw poultry requires strict temperature control. Refrigeration is a critical food safety component.

Storage Equipment Requirements

- Reach-In Refrigerators

Provide quick access to chicken, batter, and perishables during service. - Walk-In Coolers

Essential for bulk poultry storage and marinated product holding. - Commercial Freezers

Used for long-term inventory storage and frozen menu items. - Dry Storage Shelving

Keeps breading mix, spices, and packaging materials organized and protected.

read more : Fast Food Restaurant Equipment Requirements for Different Fast Food Restaurant Types

Fried Chicken Restaurant Equipment for Holding & Service

Maintaining crispiness after frying is one of the biggest challenges in fried chicken operations.

Holding & Service Equipment

- Heated Holding Cabinets

Designed to keep chicken warm without trapping moisture, preserving texture. - Heat Lamps

Used for short-term holding during peak service periods. - Dump Stations

Allow staff to season and portion fried items efficiently.

These tools ensure speed and consistency—two essential goals of any fried chicken restaurant equipment plan.

Dishwashing, Sanitation & Safety Equipment

Cleanliness and safety are not optional. Fried chicken kitchens must meet strict regulatory standards.

Mandatory Equipment

- Commercial Dishwashers

- Three-Compartment Sinks

- Handwashing Stations

- Grease Traps & Waste Systems

These items are legally required components of a compliant fried chicken restaurant equipment setup.

Ventilation & Fire Safety Systems

Frying generates grease-laden vapors and high heat, making ventilation critical.

Safety Equipment Checklist

- Type I Ventilation Hood Systems

- Fire Suppression Systems

- Make-Up Air Units

- Non-Slip Flooring

Proper safety systems protect staff, equipment, and your business license.

Kitchen Layout Tips for Fried Chicken Restaurants

An efficient layout maximizes output without increasing labor costs.

Actionable Layout Tips

- Position breading stations directly before fryers

- Separate raw poultry prep from cooked product zones

- Keep oil filtration systems easily accessible

- Design straight-line workflows to reduce cross-traffic

Smart layout decisions enhance the effectiveness of your fried chicken restaurant equipment investment.

Conclusion: Build a Profitable Kitchen with the Right Fried Chicken Restaurant Equipment

Choosing the right fried chicken restaurant equipment is the foundation of a safe, efficient, and scalable fried chicken business. From high-performance fryers and breading stations to oil management and ventilation systems, every piece plays a vital role in food quality and operational success.

By planning your equipment setup carefully, you reduce costs, improve consistency, and create a kitchen capable of handling peak demand with confidence. Invest wisely, follow best practices, and your fried chicken operation will be built for long-term success.

A well-planned layout reduces unnecessary movement, prevents cross-contamination, and optimizes staff productivity—making it a critical fast food kitchen cost factor.

Ready to upgrade your kitchen? Explore the best restaurant kitchen equipment in the UAE today and take your business to the next level. Click here to discover top-quality solutions that will streamline your operations and boost efficiency